Let us prove this to you and we are happy for IronCAD to be directly compared to any CAD system in the world, we can even help you do the comparison, many of our team (and customers) have detailed experience in a range of CAD systems. Your ROI can be returned in months because your engineers are spending time designing and not fixing crashes. This obviously then slows down the rate your designer can create your design as they are often fixing tree crashes for just small changes to a design. This is just the nature of the design methodology that history constraint drive design has to work. Thus your designers then have to spend hours fixing this problem.

Change something high up in the tree and you are often not sure of the effect which often results in complete crashes of the design. This can make editing large parts and assemblies difficult, especially, if you have forgotten your design approach. Traditional MCAD like SolidWork/Inventor/Creo etc have follow strict rules and often do a design methodology before they even start to design. This give far greater design flexibility. After all who know how you will want to change the part in the future. No longer having to spend time doing a design review before your start, just create. IronCAD's design methodology allows it to direct edit a part independent upon the previous or post step, thus making changes to any part/assembly easy. IronCAD does not suffer from the traditional history based MCAD solid modelling approach, where each step has to follow the previous step.

IronCAD likely presents the opportunity to significantly increase efficiency and therefore profitability of your company. IronCAD also has a bulk drawing tool, so you can very quickly generate drawing sheets with predefined views for every part in your model, drmatically speeding up drawing time. Furthermore, you can create separate or combined technical drawings for every individual part and assembly, all from the one 3D file. IronCAD provides a far better system from the ground up and still gives you the option to use the only beneficial feature of the traditional part system. IronCAD allows you to do this external linking without having to do it for every single part, simply choose the ones you want to save externally and you’re done.

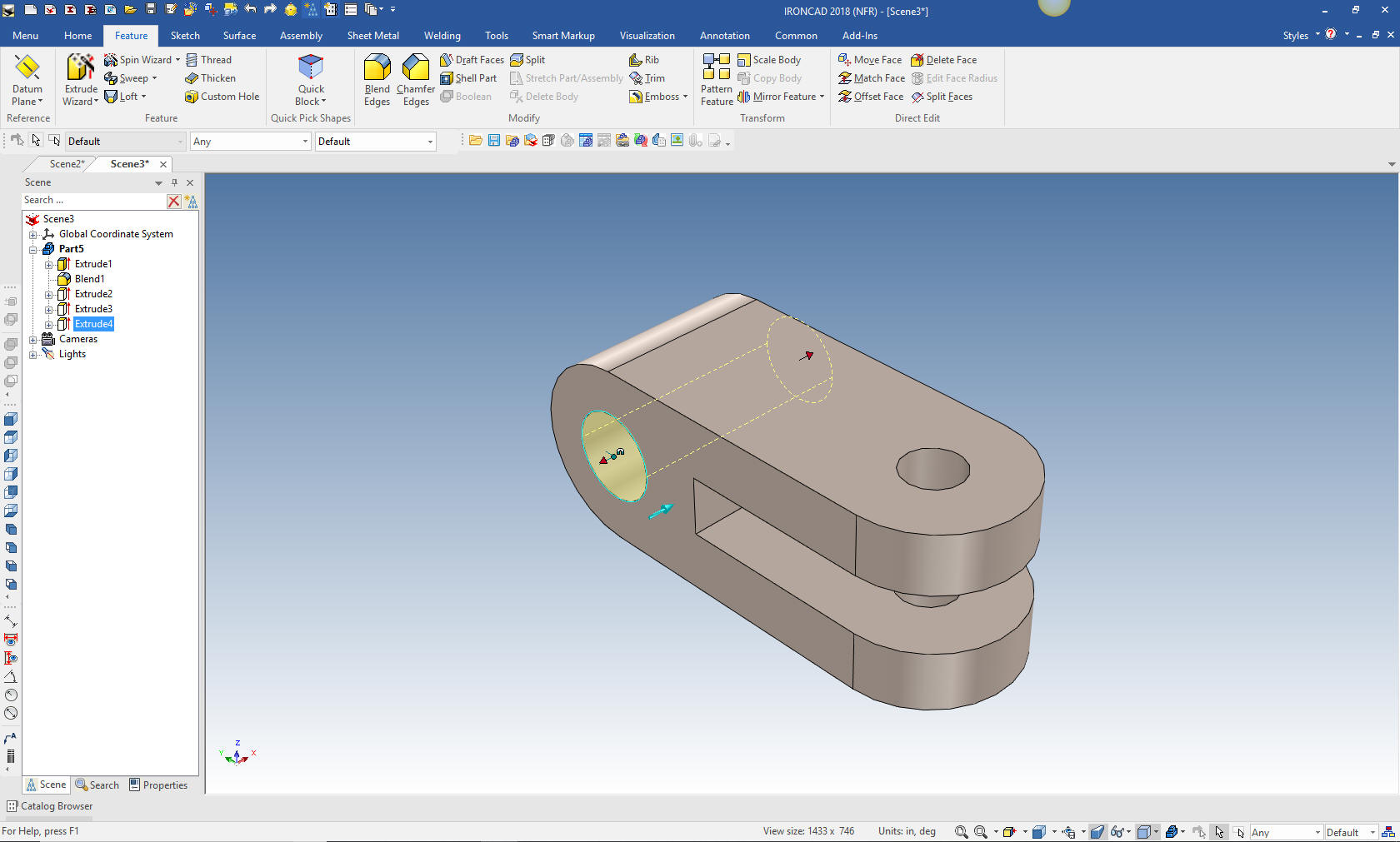

IRONCAD EXTRUDE THROUGH ALL UPDATE

The only potential positive of the traditional way is that when you have one part in multiple assemblies, you can link it to update in every assembly when a change is made. This also means you don’t have to go through the tedious process of mating all your parts together to make the assembly, everything is already in the right place and fits perfectly first time. You can also still isolate individual parts to work on them, all whilst in the same file. This is also a much more natural way of thinking about your design, you can think if the design as a whole working system. Sizing parts to fit to other components in your design, and making them fit perfectly first time. So you can design in the context of your overall assembly and design. You can build 1 part or 1 million parts in the same file. In IronCAD, part and assembly files are the same.

0 kommentar(er)

0 kommentar(er)